Production Description

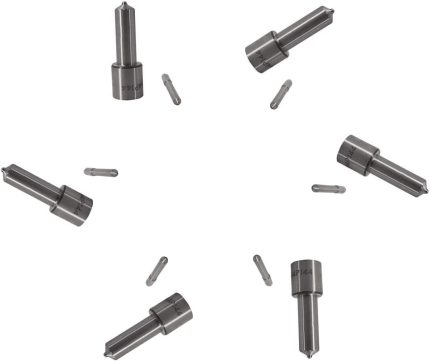

Part No.: 0433172016

Stamping No.: DLLA145P1655

| Item specifics | |||

| Condition: | New,Brand-New;Unused | Brand | DieselPartsPro |

| Type: | Common Rail Nozzle | Warranty: | 2 Year |

| Manufacturer Part Number: | DLLA145P1655 | Cross Reference OE/OEM Number: | DLLA145P1655 0433172016 |

| Fitment: | 0445120086 | Engine Compatibility/Application: | |

| Interchange Part Number: | DLLA145P1655 0433172016 | Fuel Type: | Diesel |

Product Name: DLLA145P1655 Injector Nozzle

Function of the Common Rail Nozzle DLLA145P1655

:

As a crucial component of the common rail system, the fuel injector nozzle DLLA145P1655, under the control of the fuel injector, is responsible for injecting high – pressure fuel into the engine cylinder at a specific spray angle and flow rate. This enables the fuel to mix thoroughly with the air, achieving efficient combustion, thus ensuring the engine’s power output and fuel economy. If the fuel injector nozzle malfunctions, such as getting clogged or worn out, it may cause problems in the engine like uneven

How to Detect and Maintain Common Rail Nozzle DLLA145P1655

Detection Methods

- Visual Inspection: Examine the nozzle surface for visible wear, cracks, deformation, or corrosion. Pay particular attention to the spray holes at the nozzle tip. Irregular edges or burrs on the spray holes may affect fuel injection performance. Also, check the connection between the nozzle and the injector for looseness or signs of fuel leakage.

- Injection Pressure Test: Connect a professional injection pressure tester to the common rail nozzle. Start the engine and observe the injection pressure data shown on the tester. Different models of common rail nozzles have different standard injection pressure ranges. For instance, some Bosch common rail nozzles may have a standard pressure between 1600 – 2000 bar. If the measured pressure deviates significantly from the standard value, it indicates potential issues with the nozzle, such as a clogged injector or a stuck injection valve, which prevent the normal build – up or maintenance of pressure.

- Spray Pattern Inspection: Install the nozzle on a dedicated injector test bench. Start the test bench to simulate the engine’s fuel injection process and observe the spray pattern of the nozzle. A normal spray should be uniform, fine, and distributed in a specific conical or fan – shaped pattern, with the spray angle meeting the design requirements. Uneven spraying, deflection, misting, or overly large fuel droplets suggest nozzle malfunctions, possibly caused by clogged or worn spray holes, or poor sealing of the needle valve inside the injector.

- Injection Flow Rate Detection: Measure the injection flow rate of the nozzle over a certain period using an injector test bench or specialized flow – measuring equipment. Compare the measured flow rate with the nozzle’s standard flow rate data. A certain error range is usually allowed, but if the deviation exceeds the specified value, e.g., more than ±5%, it may imply problems with the nozzle. This could be due to partially blocked spray holes reducing the flow rate or a poorly – closed needle valve causing an excessive flow rate.

- Seal Integrity Detection: Apply a specific pressure to the nozzle on the injector test bench and then observe the fuel leakage from the nozzle within a given time. If the leakage amount exceeds the allowable value within the specified time, it means the nozzle has poor sealing. This may be caused by wear between the needle valve and the valve seat, impurities getting stuck, or seal aging, which will affect the accuracy of fuel injection and engine performance.

Maintenance Methods

- Regular Cleaning: Regularly clean the nozzle with a specialized injector cleaner. An ultrasonic cleaning device can be used by placing the nozzle in a cleaning tank filled with the cleaner. The ultrasonic vibration helps remove carbon deposits, gums, and impurities inside the nozzle and around the spray holes. Generally, clean every 20,000 – 30,000 kilometers or as per the vehicle’s instruction manual. Adding high – quality fuel additives to the fuel can also help reduce carbon deposit formation in the nozzle and keep it clean.

- Prevent Impurity Ingress: Ensure fuel cleanliness by using high – quality fuel and avoiding inferior or impurity – laden fuel. Replace the fuel filter regularly, typically every 10,000 – 15,000 kilometers, to prevent fuel impurities from entering the common rail system and nozzle, which could cause blockages or wear. When refueling, choose regular gas stations to avoid those with unguaranteed fuel quality.

- Proper Use and Operation: Start and stop the engine correctly according to the vehicle’s instruction manual. Avoid frequent aggressive driving behaviors like rapid acceleration and sudden braking to reduce the impact and wear on engine components such as the common rail nozzle. During engine operation, monitor the engine’s working condition. If abnormal vibrations, power loss, or increased fuel consumption occur, promptly check the common rail nozzle and other related components.

- Regular Maintenance Checks: During regular vehicle maintenance, conduct a comprehensive inspection of the common rail nozzle, including its appearance, connection parts, and injection pressure. Also, check other components of the common rail system, such as the high – pressure fuel pump and fuel pipes, to ensure the reliability of the entire system. For vehicles that have been parked for an extended period, it is advisable to conduct a simple inspection and maintenance of the common rail nozzle before restarting to prevent blockages or sticking due to long – term inactivity.

Enhance Your Engine Performance with The DLLA145P1655 Injector Nozzle!

Looking for a reliable and high-quality injector nozzle to boost your engine performance? Look no further! Our DLLA145P1655 injector nozzle, proudly made in China, is the perfect choice for your vehicle.

Upgrade your engine with the DLLA145P1655 injector nozzle today and experience exceptional performance and reliability. Get yours now and take your driving experience to the next level!

Looking for a reliable and high-quality injector nozzle to boost your engine performance? Look no further! Our DLLA145P1655 injector nozzle, proudly made in China, is the perfect choice for your vehicle.

Upgrade your engine with the DLLA145P1655 injector nozzle today and experience exceptional performance and reliability. Get yours now and take your driving experience to the next level!