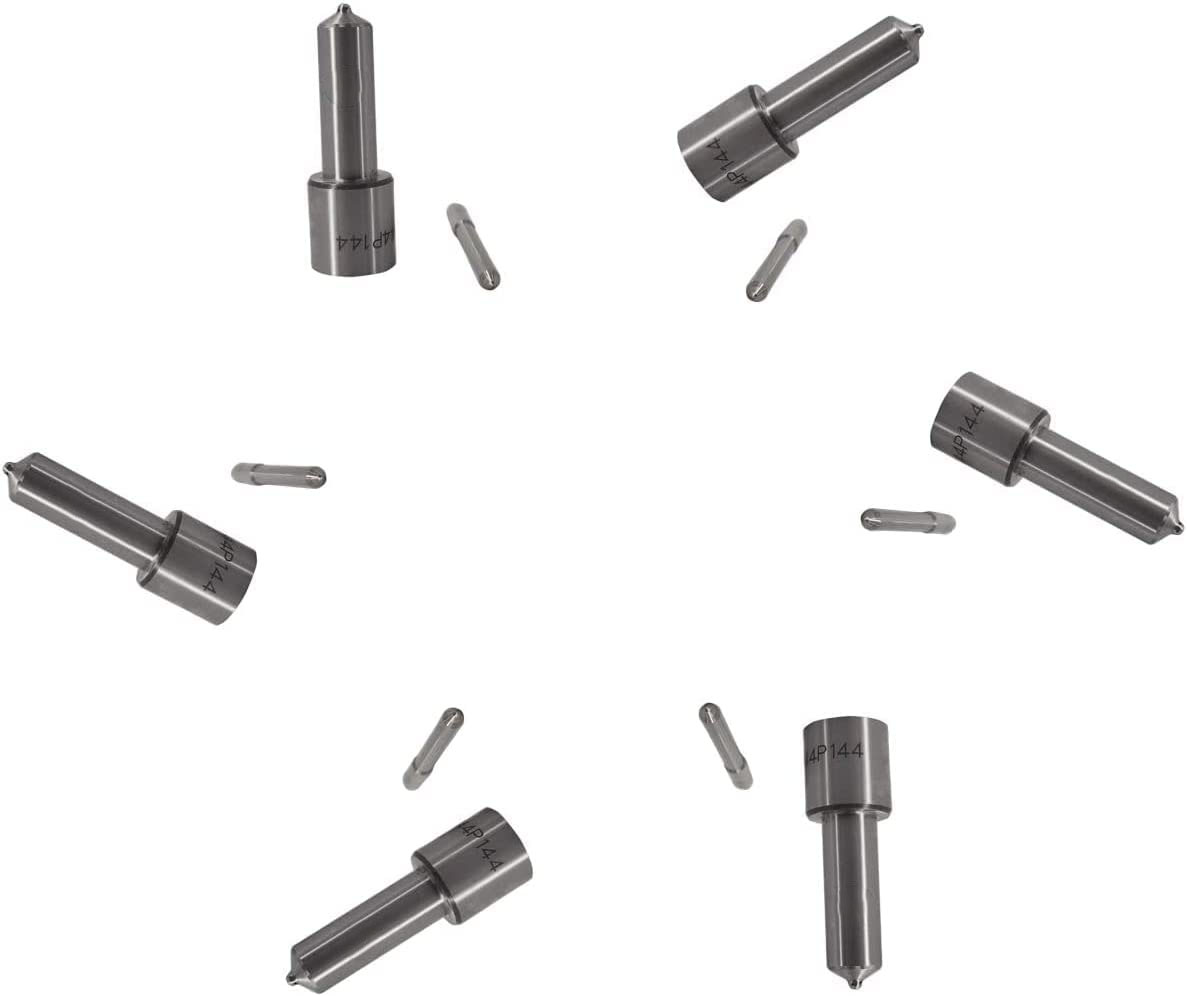

Production Description

Part No.: 0433171923

Stamping No.: DLLA139P1497

| Item specifics | |||

| Condition: | New,Brand-New;Unused | Brand | DieselPartsPro |

| Type: | Common Rail Nozzle | Warranty: | 2 Year |

| Manufacturer Part Number: | DLLA139P1497 | Cross Reference OE/OEM Number: | DLLA139P1497 0433171923 |

| Fitment: | Injector 0445 110251 | Engine Compatibility/Application: | |

| Interchange Part Number: | DLLA139P1497 0433171923 | Fuel Type: | Diesel |

The DLLA139P1497 Common Rail Injector Nozzle – your top choice for fuel injector optimization. Manufactured by XINGMA and Shumatt, this high-quality injector nozzle is designed for peak performance.

SKU Options:

– G1X9LA139P1497

– G1HX16A139P1497

– G1Z17LA139P1497

Working Principle of Common Rail Nozzle DLLA139P1497

- High – Pressure Fuel Supply: The high – pressure pump sucks fuel from the fuel tank, compresses it to a high – pressure state, and stores it in the high – pressure common rail. The high – pressure common rail stabilizes the oil pressure and distributes the fuel, providing stable high – pressure fuel to each injector nozzle.

- Fuel Injection Control

- Power – on: The Engine Control Unit (ECU) calculates the injection timing and injection quantity based on various engine operating parameters. Then it sends signals to the solenoid valve of the

- Fuel Injection: As the pressure in the control oil chamber decreases, the pressure of the high – pressure fuel in the nozzle oil chamber is greater than that in the control oil chamber. The force of the high – pressure fuel acting on the needle valve overcomes the spring force of the needle valve and other resistances, causing the needle valve to rise and the injection holes of the injector nozzle to open. The fuel is sprayed into the engine combustion chamber in a mist form and mixes thoroughly with the air.

- Power – off: When the ECU stops sending signals, the solenoid valve is de – energized, the magnetic force disappears, and the valve core returns to its original position under the action of the solenoid valve spring and the return spring, closing the oil outlet hole. The pressure in the high – pressure control oil chamber rises rapidly. When it is greater than the fuel pressure in the nozzle oil chamber, the needle valve descends under the action of the spring force and the pressure difference, closing the injection holes and ending the fuel injection.

- Precise Control of Fuel Injection Parameters: The ECU precisely controls the energization time and frequency of the solenoid valve, thereby accurately controlling the injection timing, injection quantity, and injection frequency of the injector nozzle. Under different operating conditions, the ECU adjusts the working state of the injector nozzle in real – time according to the feedback from sensors. It also adopts multiple injection strategies such as pre – injection, main injection, and post – injection to further optimize the combustion process, improving the engine’s power performance, fuel economy, and emission performance.

On – vehicle Dynamic Testing: Cylinder – cutting Test Operation Methods

1. Gasoline Engines

- Preparation: Start the engine and let it warm up to normal operating temperature. Ensure the engine is running steadily, the vehicle is in a safe testing environment with no obstacles around, the handbrake is engaged, and the gear is in neutral or park.

- Operation: Open the engine hood and locate the injector connectors. Injectors are usually near the engine’s intake manifold. While the engine is running, unplug each injector connector one by one. After unplugging each connector, closely observe the engine’s speed and vibration. You can increase the engine speed slightly for more obvious changes.

- Result Judgment: If the engine speed drops significantly and vibration intensifies after unplugging an injector connector, the cylinder is working properly. If the engine speed shows no obvious drop or only a slight change in individual cylinders, and the vibration remains unchanged, there may be problems in this cylinder, such as injector malfunctions, spark plug issues, or valve problems.

2. Conventional Diesel Engines

- Preparation: Start the diesel engine and keep it running normally. Ensure a safe testing environment and take protective measures against burns.

- Operation: Locate the high – pressure fuel pipes of the injectors. Loosen the high – pressure fuel pipe nuts of each cylinder’s injector in sequence to cut off the fuel supply to that cylinder. Be careful with the force and speed when loosening the nuts to avoid damaging the pipes or nuts.

- Result Judgment: If the running sound of the diesel engine changes significantly and the speed drops after loosening the high – pressure fuel pipe nut of a cylinder, the cylinder is working well. If there is no obvious change in speed and sound, there may be faults in this cylinder, like injector blockage or insufficient injection pressure.

3. Common – rail Diesel Engines

- Preparation: Make sure the vehicle’s power is on. The engine can be running or stationary. Connect a professional handheld tester or diagnostic tool to the vehicle’s OBD port.

- Operation: Turn on the diagnostic tool, enter the corresponding diesel engine control system menu, and select the cylinder – cutting test function. Follow the prompts to perform cylinder – cutting operations on each cylinder one by one, that is, use the diagnostic tool to cut off the fuel supply of the injector of a certain cylinder.

- Result Judgment: Observe the engine’s operating conditions, such as speed, sound, and vibration, at the moment of cutting off and restoring the fuel supply of a cylinder. If there is no obvious change in the engine’s operating conditions, there may be a fault in this cylinder.

Experience superior fuel injection efficiency with the DLLA139P1497 Common Rail Injector Nozzle – your solution for optimized engine performance.